Introduction

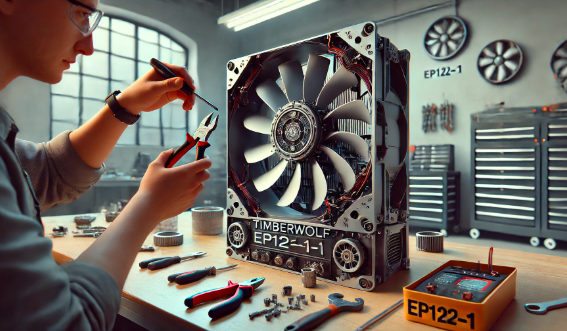

The Timberwolf EP122-1 is a high-performing heating appliance, but users often encounter an issue with fan vibration noise. This problem can disrupt the unit’s efficiency and cause unnecessary discomfort. Addressing the Timberwolf EP122-1 fan vibration noise fix promptly ensures a smoother operation and extends the lifespan of the appliance. This comprehensive guide explores the causes, troubleshooting steps, and solutions to eliminate the noise effectively.

Understanding Fan Vibration and Noise

Fan vibration and noise are common in heating appliances, and understanding their root cause is essential for an effective fix. Vibrations occur when the fan’s motion is unbalanced, often leading to an annoying humming or rattling noise.

The noise can stem from mechanical issues, dust accumulation, or improper installation. If left unchecked, excessive vibration can damage the fan motor and other internal components, leading to costly repairs.

Safety Precautions Before Troubleshooting

Before attempting any Timberwolf EP122-1 fan vibration noise fix, it is crucial to take necessary safety measures:

- Turn off the unit completely and unplug it from the power source.

- Allow the appliance to cool down before handling internal components.

- Use safety gloves and protective eyewear while cleaning or tightening components.

- Ensure adequate lighting to inspect small parts thoroughly.

Following these precautions ensures safe and effective troubleshooting.

Common Causes of Fan Vibration Noise in the Timberwolf EP122-1

Several factors contribute to fan vibration and noise in the Timberwolf EP122-1. Identifying the exact cause helps in applying the right fix. Below are the most common reasons:

| Cause | Description |

|---|---|

| Loose Fasteners | Screws and bolts holding the fan might be loose. |

| Dust & Debris | Accumulated dirt on fan blades disrupts balance. |

| Unbalanced Blades | Uneven blade weight distribution causes shaking. |

| Motor Misalignment | Improper mounting affects stability. |

| Worn Bearings | Old or damaged bearings produce rattling noises. |

| Loose Wiring | Unsecured electrical connections cause vibrations. |

Step-by-Step Troubleshooting Guide

1. Inspect and Tighten Fasteners

Over time, the screws and bolts securing the fan assembly can loosen due to continuous operation. To fix this:

- Use a screwdriver or wrench to check all fasteners.

- Tighten any loose screws securing the fan blades, housing, or motor.

- Avoid over-tightening, as it may strip the threads.

2. Clean the Fan Blades and Housing

Dust accumulation on fan blades can lead to imbalance, increasing vibration and noise.

- Use a soft cloth or compressed air to remove dirt from the blades.

- If grime is stubborn, use mild soap with warm water.

- Ensure the fan is completely dry before reassembling.

3. Balance the Fan Blades

Unbalanced blades cause excessive wobbling. To correct this:

- Check for any bent or misshaped blades.

- Use a blade balancing kit to even out the weight.

- Adjust the blade positions carefully to reduce vibration.

4. Check for Material Build-Up on the Fan Wheel

- Inspect the fan wheel for debris or residue.

- Use a brush or vacuum to remove any foreign particles.

- Ensure smooth rotation by manually spinning the fan before reassembly.

5. Inspect and Replace Worn Bearings

Faulty bearings create a grinding noise and increase vibration. If necessary:

- Locate the bearings near the fan motor.

- Check for wear and lubrication issues.

- Replace damaged bearings with manufacturer-approved parts.

6. Ensure Proper Motor Mounting

A loosely mounted motor can increase vibrations. To resolve this:

- Check the motor alignment with the fan shaft.

- Secure the mounting screws firmly.

- Use anti-vibration pads if necessary.

7. Secure Loose Wiring

Electrical wires near the fan can cause rattling noises.

- Inspect all wiring connections.

- Use zip ties or insulation tape to secure loose wires.

- Avoid placing wires too close to moving parts.

Preventive Maintenance Tips

To prevent future vibration noise, implement these maintenance practices:

- Regular cleaning: Dust and debris buildup lead to imbalance.

- Tighten components periodically: Prevents loosening due to vibrations.

- Check for worn-out parts: Replace faulty bearings and blades promptly.

- Lubricate moving parts: Reduces friction and extends lifespan.

- Schedule professional inspections: Annual servicing ensures long-term efficiency.

When to Consult a Professional

If the vibration noise persists despite troubleshooting, it may indicate a deeper issue. Seek professional assistance in the following cases:

- Persistent loud noise even after cleaning and tightening components.

- Significant damage to internal parts.

- Motor failure or unusual burning smells.

A certified technician can provide an in-depth inspection and resolve mechanical faults effectively.

Conclusion

Addressing the Timberwolf EP122-1 fan vibration noise fix ensures smooth operation, reduced wear and tear, and enhanced user experience. By following this guide, users can troubleshoot common issues and maintain the unit efficiently. Regular maintenance, prompt fixes, and professional servicing contribute to the long-lasting performance of the Timberwolf EP122-1.

RELATED ARTICLES

Comprehensive Guide to ProcurementNation.com Shipping

Dress to Impress Neopets: The Ultimate Guide for Customization Enthusiasts

Understanding Skyward HSE: The Comprehensive Guide to Health, Safety, and Environment Management